One thing that the pandemic has a positive outcome on is the technology integration and innovation across industries. Even as brands across categories were working towards getting digitally advanced and tech-savvy, Covid-19 expedited the process for them and it became more a necessity than an added advantage. With the onset of the pandemic, the world got confined to their homes and the retail operations saw a complete halt across segments, and adapting to the new normal was the only option left for these retail brands in order to stay afloat and relevant during the ongoing crisis.

While the fashion industry has been growing and developing on the back of technology for years now, it has only entered the backend processes very recently. Digitization and automation of the supply chain are important and necessary for the brands of today. In fact, 70 percent of the largest manufacturing and retail organizations across Europe and North America have already started a formal digital supply chain transformation effort. And facilitating this process of making the process as seamless and as technologically advanced is tech enabling companies like Zilingo.

Zilingo is a Singapore-based start-up launched by Ankiti Bose and Dhruv Kapoor in 2015, as an e-commerce platform for merchants to sell products to end consumers and later realized that while merchants had numerous ways to sell online in the B2C space, digitized supply chain solutions, such as expanding sourcing and procurement options, financing and downstream distribution, still were lagging behind.

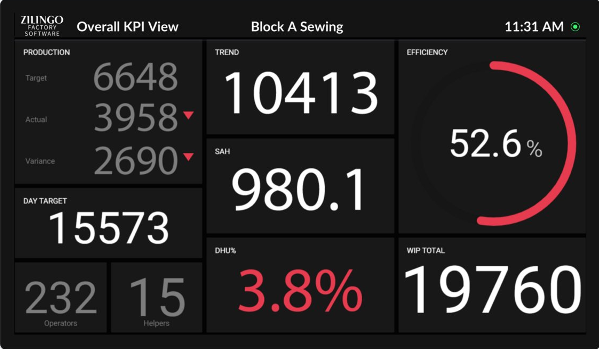

Dhruv Kapoor, Co-founder and Chief Technology & Product Officer, Zilingo, avers, “Zilingo started in 2015. Soon, we shifted our focus entirely towards B2B, with the aim to make the supply chain more transparent, fair, and connected. Our USP is that we provide our customers with technology-driven supply chain solutions and focus mainly on two aspects. Firstly, procurement of readymade and made-to-order goods on Zilingo Trade, our online platform that makes sourcing seamless and efficient, and lets brands work with our sourcing experts and our network of verified suppliers. Secondly, we work with factories in the garment industry to increase efficiency and reduce waste using Zilingo Factory, our cutting-edge MES software, which digitizes factory floors and helps in tracking quality, increases efficiency, and reduces waste. We have an end-to-end view of the supply chain since we work with brands to help them with procurement and sourcing, as well as garment factories to improve their efficiency. We believe this gives us a unique vantage point in the industry and we are able to solve problems and challenges faced at both ends.”

By 2017, it had built teams across five countries, including Indonesia, Hong Kong, Thailand, the Philippines, Australia, India, and the US. Today, Zilingo has become a unicorn valued at a little over a billion dollars and is touted as one of the largest B2B e-commerce players in Southeast Asia.

Transitioning to Offer More

Zilingo started as a B2C marketplace for markets like Thailand, Indonesia, and the Philippines, but as the co-founders went deeper into the market and interacted with more sellers, they realized that more than just being able to sell their products online, there were multiple issues ranging from logistics, supply, finance, etc.

“As we transitioned to B2B in 2017, we began to expand. India became a key market for us as we offered procurement and distribution services on Zilingo Trade to brands, suppliers, and factories. In addition, our end-to-end factory MES software, Zilingo Factory is widely deployed in India, Bangladesh, and Sri Lanka. Working with internal teams of experts and our customers, we built technology to address challenges such as sourcing made-to-order goods and helping factories optimize production using MES software. We also built strong partnerships with logistics, payments, and fintech firms. Today, we work closely with factories and provide them with lower-cost access to raw materials such as fabric and yarn, besides bringing them sourcing demand from Zilingo Trade. Further, we work with brands wherein we connect brands to our team of sourcing experts and our network of verified suppliers, and add a high degree of transparency and visibility,” maintains Dhruv Kapoor.

While Zilingo acts as an end-to-end supply chain enabler, what’s its revenue model really? So, Zilingo‘s revenue model is centered around seeking the best way to add value to its customers. While connecting its network of credible suppliers and its team of sourcing experts with its customers, the firm charges a commission from its suppliers for each order originating on the Zilingo Trade platform and also provides them with its Seller Center software to enable them to sell on Zilingo Trade and enhance their online presence. Similarly, it also charges a monthly fee instead of a high fixed cost from garment factories who have partnered with them. Zilingo does not have any in-house manufacturing facilities but the tech-based firm invests in strong partnership with its network of garment and fabric manufacturers who are verified and vetted by its team of sourcing experts.

Tech Integration and Digitization

Technological integration and digitization have become of paramount importance right now and enormous numbers of brands are now meeting technology head-on. Aiming to digitize this vast offline market is an enormous undertaking and Dhruv Kapoor is headstrong on this.

He asserts, “Technology is at the core of our business. To begin with, it's helpful to understand the challenge of digitization in the context of B2B. With B2B, there is a higher degree of variability — shipments can be the size of a carton or a container, payment could happen in multiple tranches and very often in concert with bill discounting or other forms of financing, and brands may buy either readymade or made-to-order goods. Our technology makes product discovery, search and the sourcing of made-to-order goods straightforward. Also, our technology integrates dozens of logistics providers, payment gateways, and fintech partners into our seamless checkout and order flow, making the whole process of sourcing from a factory or supplier easy and seamless. Making this seamless involves the coming together of software development, UX design, big data & data science, and of course industry expertise. Our approach is not to force-fit technology into the problem we are solving, but instead to listen to our customers and evolve our products using data & feedback. For our Zilingo Factory product, specifically, we’ve made significant investments into technology to ensure that manufacturers using our software have both a best-in-class experience and comprehensive coverage of all departments of their factory. Our team of engineers, industry specialists, data scientists, and interface designers are constantly innovating to ensure client satisfaction. This is often done by setting up hardware such as scanners to try out various solutions and simulate the actual user experience. We also reach out to our factory partners with insights about new industry trends and ideas on how to explore them. Additionally, data is imperative to improve our product experience. Finally, we invest a lot in user experience to make our products very easy to use for the entire gamut of customers we work with.”

Even as the industry was hit hard by Covid-19, this rapid move towards digital channel has led to a quick recovery and thereby profitability.

According to the McKinsey’s State of Fashion 2021 report, more than US$ 100 billion of fashion, lifestyle, and beauty consumption shifted online from offline channels over the last few months, and while overall there was a dip in demand in these categories, their digital distribution grew significantly. Being a one-of-its-kind platform, the firm was sceptical on its acceptance by the industry but factors like availability of and offerings like end-to-end software coverage on the factory floor, value for money for merchants on Zilingo Trade, cost pressures for factories, shift towards digital sourcing, supply diversification from China, vendor management inventory, etc., has helped the tech firm in aiding and accelerating acceptance by the industry players.

“Although customers can sometimes be sceptical about incorporating new technology into their business, once we demonstrate how it works and how it simplifies their sourcing, distribution, and manufacturing processes, we find that customers are quite willing to use newer technology. That being said, technology companies like us need to continue to evangelize and promote the impact of technology & supply chain digitization,” says Dhruv Kapoor.

Accelerating the tech advancement, Zilingo has onboarded logistics partners like DHL, Sicepat, Indah Cargo, Ninja Van, CJ, SCG, Neosiam, J&T Express, Lalamove, Mr. Speedy, and Grab; payment partners including Xendit, Stripe, Razorpay, Midtrans, 2C2P, Dragonpay; and financing partners in the likes of Koinworks, Modalku, Kredivo, Empatkali (part of AfterPay group), BillEase, Credit OK, PPDAI, and others.

Pushing MSMEs

According to IBEF, the SMB and MSME segment contributes to 45 percent of total industrial production and 40 percent of total exports. As per a report by the SME Chamber of India, MSMEs in the manufacturing segment accounted for 7.9 percent of GDP.

Even as this segment contributes significantly to the economy, it has been facing challenges due to the ongoing pandemic and that’s where Zilingo stepped in. Zilingo feels that technology can help in lowering barriers, making procurement faster and cheaper, and manufacturing processes more efficient and thus also cost-competitive.

“Using Zilingo Factory, MSMEs, and not just large factories, can have our software deployed in their factory & their staff trained in a matter of one week. Factories can instantly get real-time visibility into their production processes, thus spotting not just areas where defect rates or other forms of wastage are high, but also get alerted to parts of their process where they have down-time and thus underutilization of capacity. Additionally, for many smaller factories, the Zilingo Factory software helps keep track of costing & timelines of incoming orders and can even replace the need for a full-blown ERP by using our Order Module. This helps smaller factories reduce overall software costs. Using Zilingo Trade, MSMEs, including factories, brands, distributors, and retailers, can tide over procurement challenges, especially when it comes to procuring fabric, yarn, and made-to-order garments,” elaborates Dhruv Kapoor.

Challenges & the Way Ahead

Zilingo has raised US$ 308 million from Sequoia Capital, Temasek Holdings, EDBI, Burda Media, and Sofina, among others and it has strategically deployed its capital to grow the network of partners and manufacturers, build an incredible team, and to innovate and iterate on technology and product suite. Zilingo has an expansive client base and it believes in building long-lasting customer relationships by offering quality products and the overall value it adds to its customers’ businesses.

“Instead of discounting or massive paid marketing campaigns, we invest in evangelizing our value proposition through webinars, customer outreach, organic editorial opportunities and focus on improving the quality of our products and services so they can speak for themselves,” says the Co-founder of the tech-based firm.

Even as the pandemic led by Covid-19 adversely affected operations at Zilingo, the company innovated and pivoted and doubled down on focus of digitizing the supply chain with its suite of products.

“2020 was a challenging year for everyone, but it was also packed with immense learning. We made tremendous strides in terms of growing our customer base, digitising procurement of made-to-order goods on Zilingo Trade, improving the Zilingo Factory software offering, and refining our value-added services. We are more than halfway through 2021 and we have made immense progress with regards to negating the impact of COVID-19 and also helping the industry access better technology faster, in the form of our factory MES software and our online procurement solutions. As we all look forward to a more COVID-resilient future, we are also aware that apparel, fabric, footwear, and other industries still have many challenges to solve. But our mission will continue to be to listen to our customers, understand their challenges better, and find solutions to help grow their business and create powerful supply chain products for brands, factories, and distributors. Hopefully, in the process, we will be enablers of a more digital & efficient future for manufacturing, procurement, and distribution,” concludes Dhruv Kapoor.

Copyright © 2009 - 2024 Franchise India Holdings Ltd