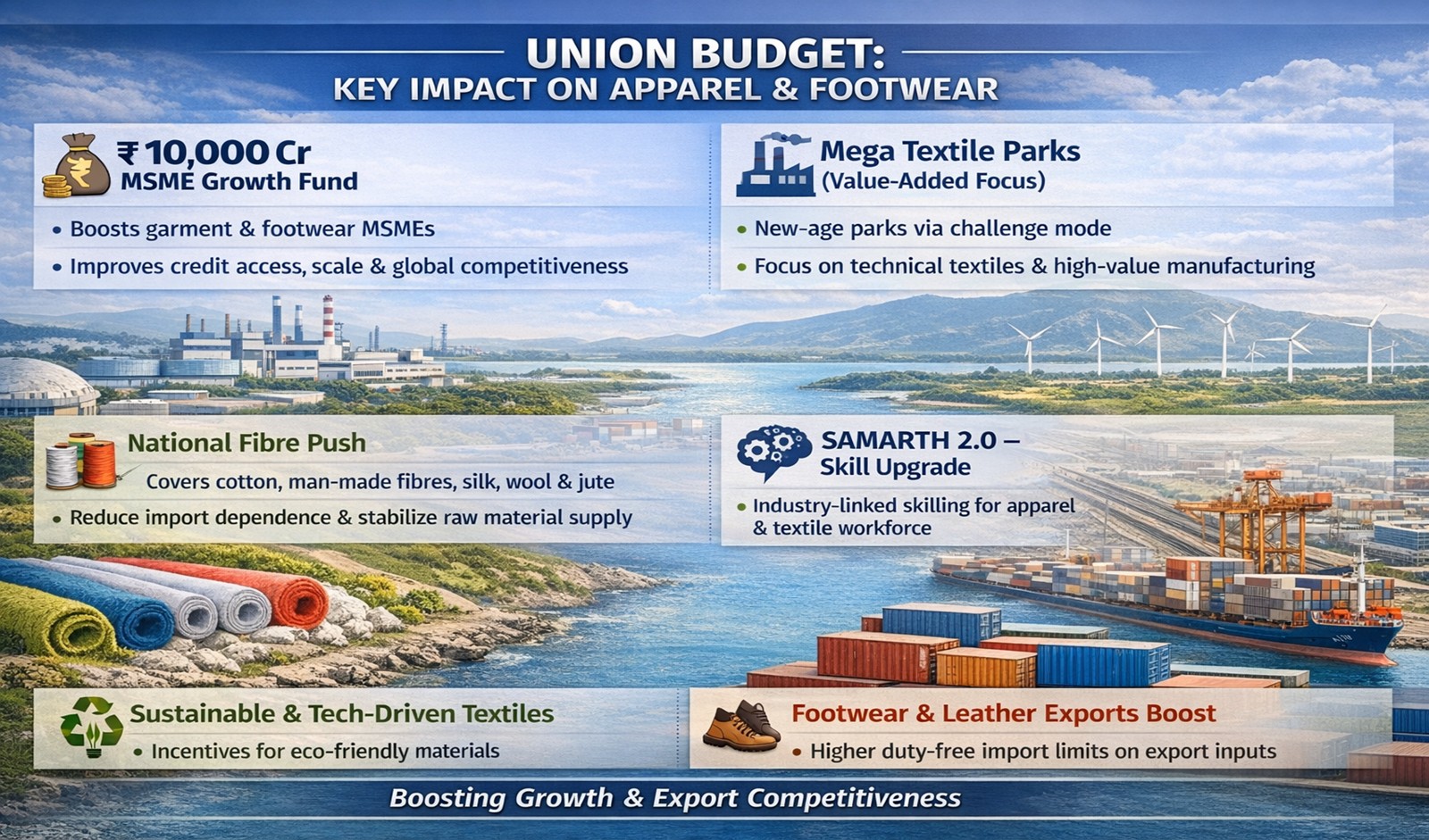

The textile manufacturing sector has long been a significant contributor to global economic growth and employment creation in numerous nations. In India, the textile industry has been highly unorganized and fragmented, with a minimal prevalence of technology usage and very low capacity utilization of about 40-50 percent. This has been a key issue for Indian textile companies as they attempt to compete in the global market. Despite the challenges, digitization presents a fresh chance for increased effectiveness and quality in the textile manufacturing sector. Textile businesses can streamline processes, lower expenses and boost production by utilizing digital technologies.

The efficiency and quality issues facing the Indian textile manufacturing sector are of no small importance. Low capacity utilization rates restrict the ability of companies to expand and become more profitable. About 83 percent of the country’s textile industry comprises unorganized small and medium enterprises, however, with technology, these businesses can increase their operational efficiency and create top-quality goods. Technology can also benefit textile businesses by lowering costs, boosting productivity, and enhancing overall competitiveness.

Increased Efficiency

For textile companies, inventory management is a big problem because they frequently have too much or too little of it. This is brought on by a lack of managerial experience and demand forecasting skills. However, textile firms can enhance their inventory management and production planning by utilizing the appropriate technologies and digitizing their operations. Barcode scanning and automated inventory replenishment systems are two of the ways to carry out digitization successfully.

Predictive maintenance is very important as, often, machines or production units are not maintained well, leading to very low average utilization of the factory. Avoiding downtimes can be made possible by deploying IoT-enabled equipment and devices for preventative maintenance. Textile manufacturers can enhance every step of their production process, from distribution to sales, by utilizing technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). Additionally, by using AI in manufacturing, companies can anticipate defects and fix them before they become bigger problems.

Indian textile manufacturers tend to lose ground to Bangladesh, Vietnam, and Indonesia as global clients are reluctant to source multi-textile materials from India due to a lack of trust and consistency in quality. Improved efficiency brought on by digitization will help the textile industry to direct its focus more on generating goods of greater quality and securing the trust of international buyers.

Sustainability

The global textile industry is one of the most pollutant-releasing industries in the world, with a very high amount of waste and causing 20% of the world’s water pollution. With the help of nanotechnology, factories can make their manufacturing more water-resistant, energy-efficient, and sustainable.

Digitization is also extremely important in order to ensure the traceability and tracking of resources. It is vital to demonstrate and validate that the materials used were grown under the proper conditions. Sustainable practices are being implemented by organizations like the Better Cotton Initiative (BCI) and Cotton Made In Africa, but monitoring those practices gets challenging for them as well. Companies can have more visibility and traceability of their resources, and ensure that they are cultivated and manufactured in sustainable ways, by digitizing the entire supply chain from farm to fashion. This will provide real-time information on the quality of the materials. Due to its highly unorganized nature, the Indian textile industry has been lagging in leveraging data-driven decision-making.

Deploying Data

Manufacturers can leverage data-driven operations to increase optimization, reduce unwarranted consumption of raw materials and streamline production processes. Information on goods that move along a production line, such as yarn density, temperature, and weight, is recorded by measuring systems. With the help of digitization in manufacturing, systems will be able to coordinate the vast amount of information in real-time with all the machines in the production process that require the data to control the fabric. Data collection in real-time will help in faster identification of inefficiencies and response to any deviations.

Decision-Making

Companies can obtain important insights into market circumstances, consumer behavior, and a variety of other aspects by using data and price trend analysis. This can help them make more informed decisions, which can ultimately result in higher revenues and profits, for both buyers and suppliers. By analyzing historical data and spotting patterns and trends, a company can obtain a deeper understanding of the forces that shape its market, and use that knowledge to make more informed decisions about pricing, manufacturing, and other aspects of business operations.

India's textile manufacturing sector must move towards digitization to increase productivity, quality, inventory control, sustainability, and decrease waste. Given that the textile industry is also one of the most polluting in the world, it is critical that while aiming for growth, action is also taken to mitigate the collective environmental impact.

A rare alignment of structural undersupply and surging consumption is powering India’s organized retail resurgence — and investors are taking note. At a time when several Western markets continue to grapple with mall closures and muted footfalls, India’s retail real estate sector is moving in the opposite direction. The country’s per-capita retail stock remains among the lowest globally, creating a supply-demand dynamic that is structurally favorable for long-term growth.

According to Anarock research, Tier I cities in India offer just 4–6 sq ft of retail space per person, while Tier II and III markets trail even further at 2–3 sq ft. Grade-A mall space averages barely 0.6 sq ft per capita — a stark contrast to nearly 23 sq ft in the United States. The gap is not merely statistical; it represents a deep, persistent shortage of high-quality, organized retail space.

This undersupply is unfolding alongside India’s transformation into a projected $6 trillion consumption economy by 2030. Rising incomes, rapid urbanization, formalization of retail, and a young, aspirational demographic are reshaping spending patterns. Organized retail is emerging as one of the primary beneficiaries of this structural shift.

The leasing numbers tell a compelling story. Approximately 3.2 million sq ft of retail space was absorbed in Q3 2025 alone — a 65 percent year-on-year jump — with Delhi/NCR and Hyderabad leading activity. Vacancy levels in high-quality malls are tightening, rental values are appreciating, and trading densities are strengthening, reinforcing the sector’s investment appeal.

But this growth is not being driven by scale alone. It is being powered by reinvention.

From Construction to Curation

India’s new-age retail developments are no longer just about adding square footage. They are about creating experiences. Harinder Singh Hora, Founder Chairman, Reach Group, emphasizes that developers are aligning retail assets with experience-led and omnichannel strategies. Physical stores are increasingly integrated with digital platforms for fulfillment, returns, and customer engagement. In this evolving ecosystem, success is defined not merely by size but by design, curation, and seamless consumer journeys.

“Retail today is about curation, not just construction,” he noted. High-quality design, accessibility, compliance, efficient parking, and a thoughtfully curated tenant mix are essential ingredients. Developers delivering immersive, lifestyle-oriented retail environments with a clear consumer proposition are witnessing faster leasing momentum and stronger brand commitment.

Malls are being repositioned as lifestyle hubs — destinations that combine fashion, food, entertainment, wellness, and social interaction. The goal is to increase dwell time and drive repeat visits, thereby enhancing tenant sales and rental predictability.

NCR: The Consumption Powerhouse

If there is one region that encapsulates this transformation, it is Delhi NCR. The region continues to drive some of the strongest retail leasing activity in the country. Sustained growth in NCR has been supported by high footfalls, rising household affluence and a marked shift toward lifestyle-driven consumption. Retail assets are no longer transactional spaces; they are social and experiential centers.

Jatin Goel, Executive Director, Omaxe Group, observes that India’s organized retail sector is entering a high-investment growth cycle, supported by robust leasing and growing institutional interest. Delhi NCR consistently ranks among the leading markets, with tightening vacancies and appreciating rentals strengthening its position as a stable yield asset.

Importantly, retail momentum in NCR is closely intertwined with residential growth. Strong housing sales, declining unsold inventory, and the outward expansion of urban belts across Gurugram, Noida, Greater Noida, and Faridabad are creating dense, consumption-ready catchments. As these residential clusters mature, demand for organized retail is deepening across both established and emerging corridors.

Emerging micro-markets such as Dwarka and Faridabad are witnessing accelerated absorption, driven by infrastructure upgrades and expanding residential bases.

Integrated developments are reflecting this new thesis. Destinations such as Omaxe Chowk in Chandni Chowk and World Street in Faridabad exemplify large-scale, experience-led retail formats that blend heritage appeal, infrastructure connectivity, and curated tenant strategies.

Beyond the Metros: The Tier II Push

While NCR and other metros remain at the forefront, the next wave of growth is steadily moving beyond traditional urban strongholds. Tier II cities, including Lucknow, New Chandigarh, and Indore, are recording rising pre-commitments from national and international brands as organized supply expands. Improved connectivity, rising disposable incomes, and increasing brand awareness are transforming these cities into viable retail destinations.

Tourism and pilgrimage-driven economies are also emerging as compelling retail micro-markets. Cities such as Ayodhya and Vrindavan are witnessing year-round visitor footfall, creating opportunities for organized retail formats aligned with hospitality and infrastructure upgrades.

This geographical diversification signals a broadening consumption base and reduces concentration risk for developers and investors alike.

Capital Flows Follow Consumption

India’s retail real estate story is not only attracting domestic developers but also global capital.

An estimated $3.5 billion is expected to be invested in India’s retail real estate over the next three years. This reflects a visible rotation of institutional capital toward markets offering both growth and stability.

Organized retail is gaining prominence within REIT and institutional investment strategies, given its ability to deliver stable annuity income supported by long-term leases. High occupancy levels, improving rental trajectories, and resilient consumption demand are positioning retail as a defensive yet growth-oriented asset class.

Mitul Jain, Managing Director, SPJ Group, highlights that projects anchored by F&B, entertainment, and lifestyle brands are generating higher dwell times and repeat footfalls. This strengthens tenant sales performance and translates into predictable rental yields for owners.

Bhupindra Singh, COO, RISE Infraventures, adds that experience-driven retail integrated with offices, residences, and hospitality creates captive audiences and ensures all-day activity. Such mixed-use ecosystems are increasingly preferred by investors seeking long-term, stable income streams rather than short-term speculative gains.

The Road Ahead

India’s organized retail sector stands at a pivotal moment. Structural undersupply continues to create a favorable demand-supply imbalance. Consumption growth is broad-based and deepening. Capital markets are increasingly aligned with long-term retail real estate strategies.

Yet the next phase of growth will depend on adaptability. Developers must continue to prioritize experience, digital integration, sustainability, infrastructure alignment, and tenant curation. Simply adding inventory will not suffice; differentiation will define success.

As India advances toward its $6 trillion consumption milestone, organized retail is poised to remain a core pillar of the country’s economic expansion. The growth story is no longer just about building malls — it is about building destinations, ecosystems, and experiences.

In a global environment where retail assets face uncertainty, India’s organized retail market stands out for its structural depth, demographic momentum, and capital appeal. Undersupplied and evolving, it is fast emerging as one of the most compelling long-term real estate plays in the world.

India for centuries has been the land of the faithful and the religious. And for generations, countless Indians and Westerns turned to faith through neighbourhood temples, priests, and small kiosks tucked into busy streets. But the times have changed.

Historically, spiritual products and services accessed through hole-in-the-wall shops and temple adjacent stalls, and trusted neighbourhood vendors were channelled through an ecosystem built on familiarity, trust, and confidence. It has fast grown into millions of customers, countless platforms, and an elaborate market exceeding billions in market-value.

The New e-Spiritual Market

Thanks to the internet and digital platforms, this market has transformed the manner in which spiritual services reach people. E-commerce and quick-commerce platforms have not only bettered the service-standard but provided value to the faithful customer. These platforms have evidently transformed India’s spiritual market - which is projected to double by 2034 from $70 billion in 2025. According to Datum Intelligence, quick-commerce platforms already account for roughly a tenth of India’s Rs 900 crore spiritual products segment.

Besides economic opportunity, these numbers reflect a deeper transformation of a traditionally fragmented hyper-local sector in gradually finding structure through organised platforms. More than just convenience, this indicates growing consumer comfort in accessing faith-based products through digital channels, where transparency and reliability are increasingly expected.

Beyond Products

The transformation in India’s rich spiritual services and faith-tech extends well beyond physical goods and includes online pujas, astrology consultations, matchmaking services, devotional content, and ritual bookings.

Online platforms have curated categories for puja essentials, idols, and festival-specific products. These are complimented with good pricing standards, delivery timelines, quality assurances and an experience like never before.

Startups and digital platforms in this space have made it possible for devotees to engage with spiritual practitioners irrespective of their geography. In temple cities, such as Ujjain, for instance, priests are technologically equipped to conduct online pujas via video calls and livestreams. Bookings for the Ujjain temple have risen sharply during peak periods such as Shravan with travellers able to book their tickets online. On a broader context, the Indian diaspora outside of the country has managed to engage with their religion without dependence on travel or intermediaries.

This shift is not merely technological as it is deeply enabling artisans, priests, astrologers, and small service providers. These stakeholders once depended on local footfall, and can now access national and international audiences through the internet. With integrated logistics, digital marketing, and discovery tools, traditional practitioners are finding new relevance in a digital-first world. In many ways, this mirrors the evolution of Ayurveda and wellness, where ancient knowledge systems found renewed reach through structured delivery and regulatory clarity.

Transparency = New Trust Anchor

One of the most meaningful contributions of digital platforms has been the introduction of clarity into a space that traditionally relied on informal, relationship-driven norms. Products now come with defined descriptions, visible pricing, authenticity assurances, and return policies; features that were often absent in small local outlets or temple-side kiosks.

This shift has had a tangible impact on consumer behaviour. Research by 360 Research Reports shows that buyers are willing to pay a premium for ethically sourced and authenticated spiritual goods, particularly in categories like gemstones, idols, and ritual kits. Trust, once built purely on personal relationships, is now increasingly reinforced by platform-enabled verification.

Standardisation has introduced much-needed accountability as sought by customers and platform providers. Many platforms now verify practitioner credentials, display certification standards, and maintain service transparency helping consumers engage with spirituality with greater confidence.

Responsibilities Of Scale

While the transformation is engaging and benefits stakeholders, the greater reach comes with greater responsibility. While digital access has democratised spiritual services, it has also lowered barriers for fraudulent actors. Operating on the internet does pose challenges around the risks of over-commercialisation, misuse of consumer data, or dilution of authenticity which needs to be managed accordingly.

Businesses and platforms engaged in the spiritual space need to apply reasonable solutions in areas such as ethical sourcing, practitioner verification, data privacy, and grievance redressal mechanisms. As the sector matures, regulations will have a tall bearing but the industry can survive only if these approaches are consistent and transparent.

New Chapter in India’s Spiritual Ecosystem

India’s spiritual sector is gradually moving from fragmented, localised access to a more structured and transparent digital presence. For consumers, this brings confidence,

convenience, and choice while it delivers scale and sustainability for service providers. It does connect faith providers with faith seekers and does so without hampering cultural roots.

If guided responsibly, this digital evolution will strengthen India’s spiritual traditions and even render them more accessible, credible, and resilient in a modern context. Faith, after all, has always evolved with time. Today, it is simply finding its place, but this time on the screen.

Authored by:

Daman Soni, Chief Business Officer, Astrotalk Store

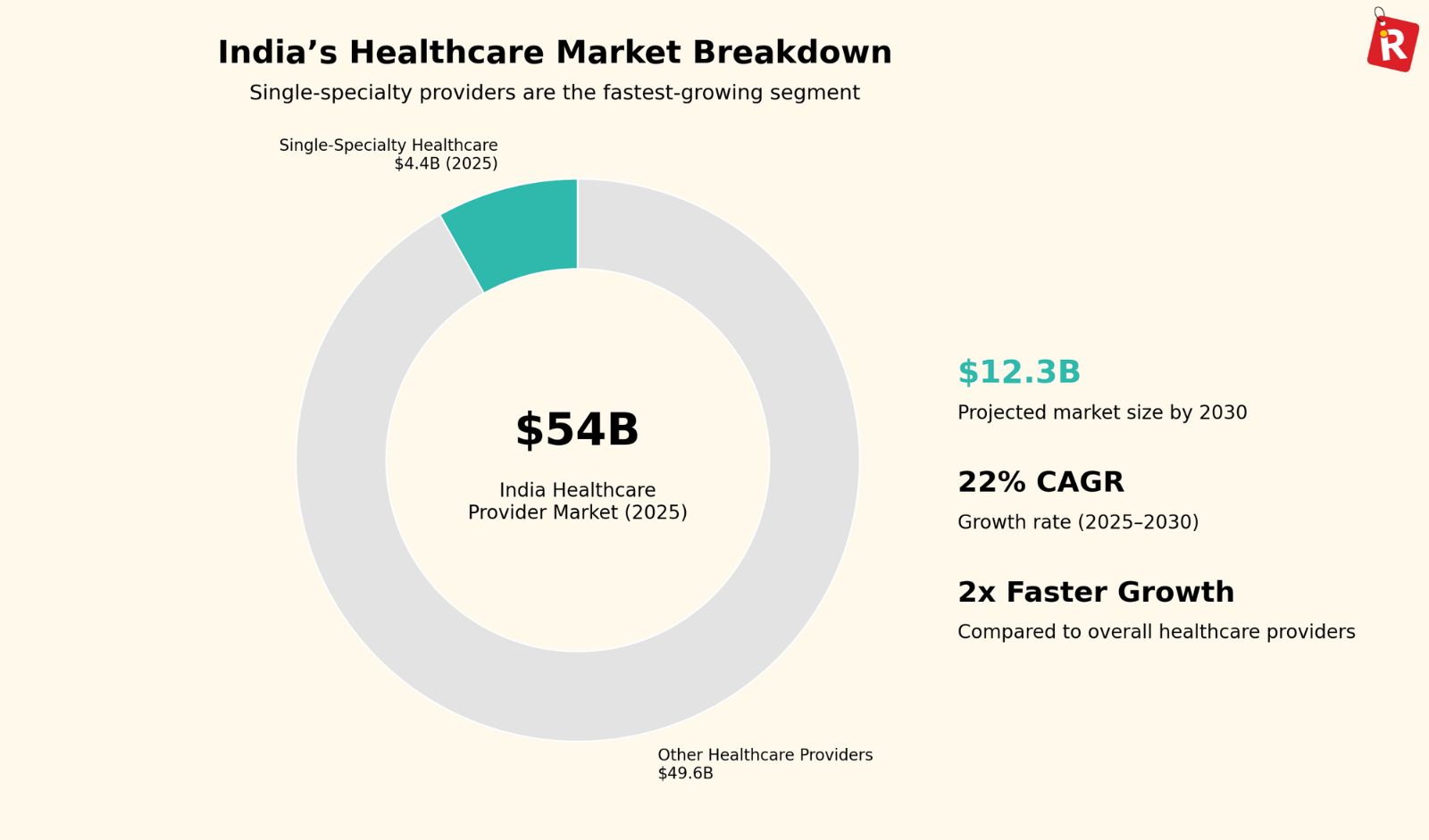

India’s organised retail sector may be growing, but a large part of it is quietly losing money — right at the shelf. A new knowledge report by Vector Consulting Group reveals that 91 percent of organised retail stores experience revenue leakage at the shelf level. The Ticking Shelf: The Overlooked Economics of Store Performance report is based on insights from CXOs and heads of 100 organised retail chains with annual revenues exceeding Rs 500 crore.

The Scale of the Problem

Despite strong category growth and network expansion, 28 percent to 40 percent of stores across formats continue to operate below profitability. This persistent tail of underperforming outlets suggests a deeper structural issue in how store-level economics are managed.

Retailers are expanding, categories are growing, and assortments are widening — but the core driver of profitability at the store level is being overlooked.

Shelf Throughput: The Missing Metric

At the heart of the issue is shelf throughput — the speed at which revenue and margin are generated per square foot, per day. While most retailers track metrics like sales per square foot or GMROI, only 9 percent actually use shelf velocity to guide daily decisions such as buying, replenishment, and display planning.

Without linking shelf performance to everyday operational decisions, stores struggle to maintain freshness and speed.

Ageing Inventory Eating Into Margins

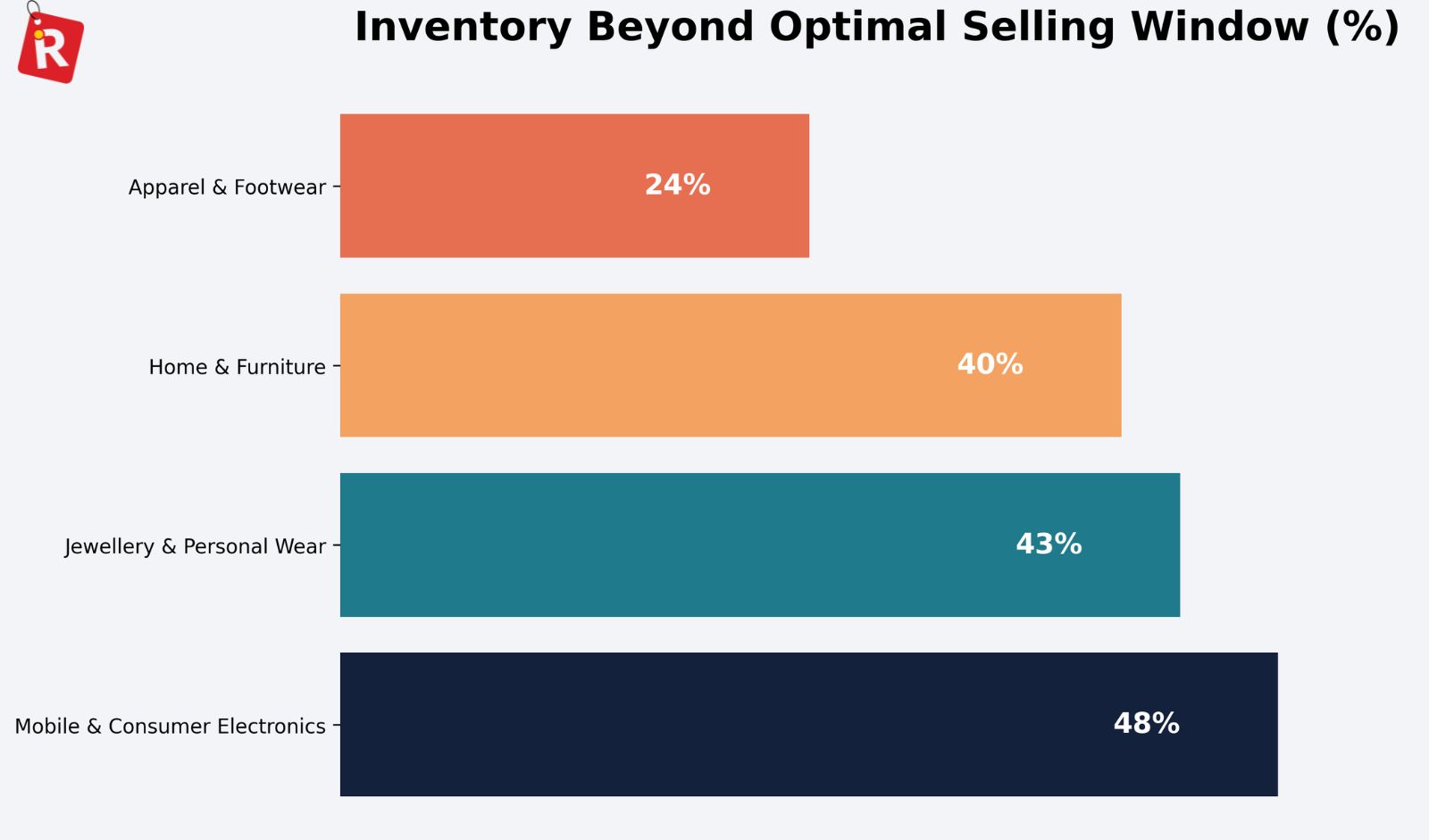

One of the biggest concerns highlighted in the report is ageing inventory occupying valuable shelf space.

In Mobile & Consumer Electronics, 48 percent of on-shelf products remain beyond their optimal selling window. Apparel & Footwear reports 24 percent, Home & Furniture 40 percent, and Jewellery and Personal Wear 43 percent. When slow-moving products sit on shelves for too long, they crowd out new launches and reduce the opportunity to sell at full price.

Additionally, 83 percent of stores do not update planograms regularly, and 91 percent report that slow movers block space for new product introductions. Over time, this quietly erodes shelf productivity and margins.

The Cost-Efficiency Trap

According to P. Senthilkumar, Senior Partner at Vector Consulting Group, retailers often focus heavily on protecting margins. To lower unit costs, they accept long lead times, buy in bulk, and continuously expand SKU portfolios.

While these practices improve cost efficiency on paper, they increase total inventory in the system. When demand does not materialise as expected, ageing stock builds up quickly.

Corrective actions such as markdowns, transfers, or pullbacks are often delayed. Around 66% of retailers view markdowns as margin erosion, while 48 percent see corrective measures as additional costs. As a result, ageing inventory is managed reactively instead of through structured rules. In fact, 65 percent of retailers lack strong processes to maintain inventory freshness.

Managing Shelf Space as a Perishable Asset

The report argues that shelf space should be treated as a perishable asset. Every day that a product does not sell represents a lost opportunity. With limited shelf space and expanding assortments, retailers need disciplined systems to ensure constant churn.

The study recommends rule-based subordination of retail operations to shelf throughput. This includes limiting SKU expansion, allocating space based on performance, enabling faster replenishment, ensuring early exit of slow movers, and quickly deploying proven high-performing products. Automation, regular visual merchandising reviews, and consistent staff training are essential to sustain these practices at scale.

Kumar Rajagopalan, CEO of the Retailers Association of India, said the report provides valuable methods to improve profitability by focusing on shelf productivity and asset efficiency.

The Way Forward

The message is clear: topline growth alone does not guarantee profitability. Stores that maintain freshness, improve velocity, and increase throughput generate stronger returns, faster inventory turns, and better margins.

In modern retail, the shelf is a ticking clock. Retailers that manage it proactively will win. Those that do not will continue to leave money on the shelf.

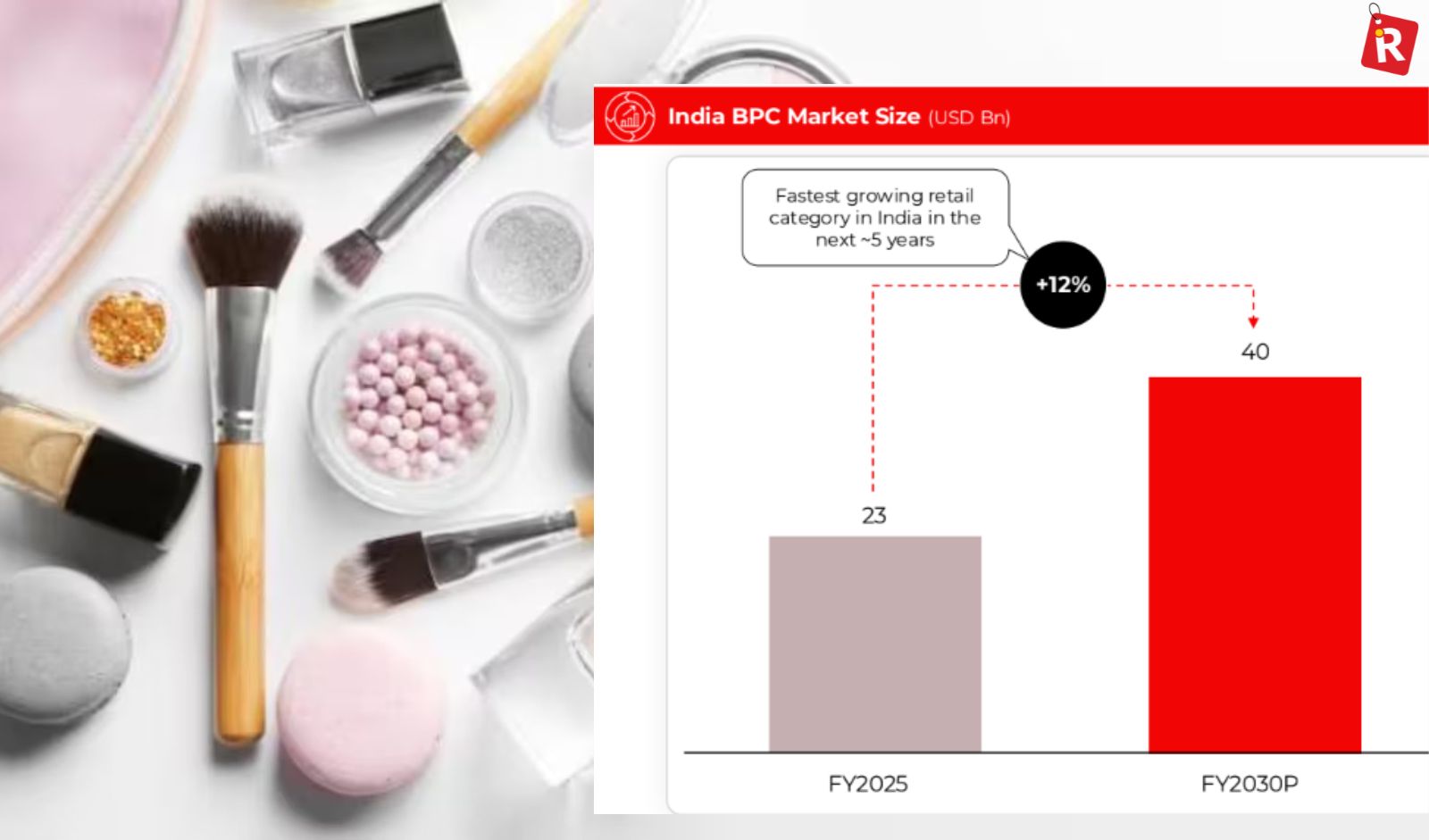

If you walk down any beauty aisle in India today, you’ll notice something that was barely true a few years ago: global beauty is no longer niche here. From premium counters in malls to dedicated sections on e-commerce sites, beauty brands in India are becoming genuinely international. What’s driving this shift? Indian consumers are more curious, informed, and willing to try global formulas — whether it’s an american beauty brand with cult skincare cult status, a chic french beauty brand, or a trendsetting korean beauty brand with a two-step routine you can’t stop hearing about.

At the same time, more Asian labels — especially japanese beauty brands — are bridging function and feel, making them favorites among everyday users.

Why International Beauty Brands Are Finding India Irresistible

India is a unique mix: large population, rising disposable income, beauty-savvy shoppers, and high digital engagement. That’s a rare combo. Take a label with a loyal following in Korea, France, Japan, or the U.S., and you’ve got an audience here ready to explore it — if it’s accessible, relevant, and delivers results.

This is why american beauty brands, korean beauty brands, french beauty brands, and japanese beauty brands are racing to expand here. Whether they enter through luxury retail partners, local distribution deals, or direct-to-consumer e-commerce, the strategy is about making products feel right at home — even if their heritage is global.

How India’s Beauty Landscape Is Evolving

The idea of beauty in India is no longer rigid. It’s not just “fairness” creams or festival glam anymore. Consumers want hydration, glow, serum performance, clean ingredients, texture innovation, and formula transparency. They trust reviews. They compare ingredients online. They even gravitate toward international trends — lightweight essences from Japan, hyaluronic serums from Korea, long-wear primers from the U.S., and elegant packaging from France.

In short, people are curating their personal beauty language, and international players are giving them more ways to speak it.

Top International Beauty Brands Expanding Aggressively in India

1. Estée Lauder

Estée Lauder is one of those luxury beauty brands that feels instantly aspirational yet practical. Its presence in India has grown not just in major metros but also in emerging urban markets where people are looking for performance skincare with visible results. Known for powerful serums, iconic foundations, and age-defying treatments, Estée Lauder appeals to consumers who want effectiveness without guesswork. The brand’s expansion reflects deeper shifts: Indians are no longer afraid to invest in premium skincare and makeup if it actually delivers. That’s why Estée Lauder sits comfortably among the top beauty brands in India today — it’s recognizable, results-driven, and has built strong trust over repeated use.

Read more: Best 8 Cosmetics Brands Trending on Instagram and Quick Commerce

Top 7 Best Hair Serum Brands for Women Driving Growth in India’s Beauty Retail

Top 6 Shampoo Brands to Control Oily Hair and Greasy Scalp

2. L’Oréal Paris

L’Oréal Paris is the textbook example of a global beauty powerhouse that knows how to localize without losing identity. As one of the most visible french beauty brands in India, it has carved out space across skincare, haircare, and makeup. What makes L’Oréal stand out is its combination of high-end technology with everyday wearability. A serum from L’Oréal can feel premium yet not intimidating, and a lipstick can feel both comfortable and trendy. This accessibility, combined with strong distribution — from urban boutiques to local cosmetics stores — has made it one of the best beauty brands in India across segments. Its constant innovation keeps it both relevant and in demand.

3. Shiseido

Shiseido’s expansion in India reflects the growing curiosity about high-touch Asian skincare — and why japanese beauty brands are no longer niche here. Shiseido excels at blending science with sensorial formulas that feel luxurious on the skin. Its essences, sunscreens, and moisturizers are loved for being effective without heaviness — a balance Indian weather makes particularly appealing. Shiseido doesn’t just sell products; it sells a ritual centred around hydration and skin health. That resonates deeply with consumers moving beyond quick fixes to routines that feel good to use every day. As a result, Shiseido continues to expand its footprint and fan base across beauty-forward Indian consumers.

4. Laneige

When you talk about korean beauty brands in India, Laneige effortlessly comes up in conversations about glow and hydration. Thanks to its rich yet lightweight formulas and signature water-science technology, Laneige has become especially popular among younger users who want skin that reflects natural radiance, not heavy makeup. Its Water Sleeping Mask and Lip Sleeping Mask have cult status online, driving both curiosity and sales. What’s interesting is that Laneige didn’t rely solely on premium malls — it built buzz through social platforms and sampling culture, making K-beauty part of everyday routines. That strategy has helped it scale quickly and organically across cities.

5. Fenty Beauty

Fenty Beauty is an example of an american beauty brand that grew fast not because of heritage, but because it solved a real problem — namely, shade inclusivity and formulas that flatter a wide range of skin tones. Its expansion in India has been more than retail footprints; it’s brand culture. Lip glosses, foundations, and highlighters that actually look good in Indian skin tones generate repeat buying and word-of-mouth buzz. Fenty’s approach — bold, expressive, and inclusive — resonates strongly with younger shoppers who see beauty as identity, not just routine. That’s why it’s one of the most talked-about beauty product brands in India right now.

Know more: Summer Skincare Routine for Oily Skin in India

Top Chinese Alcohol Brands Entering India’s Premium Spirits Market

Top American Fashion Brands Expanding Aggressively Across India’s Fashion Retail Market

Market Insight: Why International Beauty Brands Are Growing Faster Than Ever

Indian consumers are no longer passive buyers — they have opinions, preferences, and global reference points. They watch tutorials and compare ingredients. They’re as likely to discover a Japanese essence as a Korean sheet mask or an American foundation. This cross-pollination of beauty habits has created fertile ground for international beauty brands.

Another big factor is omnichannel accessibility. You don’t need a luxury boutique membership to try a premium serum anymore. E-commerce platforms, beauty-specific apps, and digital sampling programs have made it easy to explore global brands from north to south, metro to non-metro.

Finally, social media accelerates trends in real time. A Korean lip tint trend can be a chicara makeup table staple within weeks; a French anti-aging serum can sell out overnight after a beauty influencer review. That’s the new reality shaping how beauty brands expand — and why India matters.

Conclusion

India’s beauty market is becoming one of the most exciting playgrounds for international beauty brands. American, French, Japanese, and Korean names are not just entering — they’re embedding themselves in local routines. What used to be aspirational has become attainable and relevant. From performance serums to trendy makeup essentials, the top beauty brands in India today are those that balance global excellence with local resonance.

FAQs on Top International Beauty Brands in India

1. Which international beauty brands are most popular in India?

Brands like Estée Lauder, L’Oréal Paris, Shiseido, Laneige, and Fenty Beauty are among the fastest-growing in India.

2. Are Korean beauty brands gaining traction in India?

Korean beauty brands like Laneige are especially popular for hydration and glow-focused products.

3. Do French beauty brands work well for Indian skin types?

Yes. Many french beauty brands tailor formulas that balance sensitivity, humidity, and long-wear performance.

4. Are American beauty brands adapting to Indian preferences?

Brands like Fenty and Estée Lauder localise shade ranges and textures while maintaining global quality.

India’s alcoholic beverage industry is undergoing a structural shift. While whisky continues to dominate consumption, the premium and luxury spirits segment is expanding rapidly across metros and tier I cities. According to industry estimates by IWSR and Confederation of Indian Alcoholic Beverage Companies, India’s premium spirits market has been growing in high single to low double digits annually, driven by rising disposable incomes, exposure to global drinking culture, and the expansion of modern retail and on-trade formats. Imported spirits account for a small but fast-growing share, particularly in the super-premium category.

Within this evolving landscape, Chinese alcohol brands are beginning to explore India as a strategic growth market. From traditional Chinese baijiu brands to globally recognised Chinese beer brands and boutique Chinese wine brands, producers are positioning themselves to tap into India’s growing appetite for premium international labels. While still niche, the entry of Chinese alcohol brands in India reflects a broader diversification of global spirits on Indian shelves.

Why Chinese Alcohol Brands Are Looking at India

China is home to one of the world’s largest alcohol markets, particularly in baijiu, which remains the country’s dominant spirit category. As domestic competition intensifies and global trade corridors expand, several popular Chinese alcohol brands are seeking overseas markets.

India presents a compelling opportunity for three reasons:

- A fast-growing premium consumer base

- Increasing interest in global spirits beyond Scotch and vodka

- Expanding luxury hotel, fine-dining, and cocktail culture

Although regulatory challenges and import duties remain significant, select premium Chinese alcohol labels are being introduced through niche distributors, diplomatic channels, and high-end hospitality networks.

Below are some of the Top Chinese Alcohol Brands that are either entering or exploring India’s premium spirits market.

1. Kweichow Moutai – The Icon of Chinese Baijiu

![]()

Often regarded as the face of best Chinese liquor, Kweichow Moutai is China’s most prestigious baijiu producer. Distilled from sorghum and wheat using traditional fermentation techniques, Moutai’s flavour profile is complex, savoury, and aromatic, often described as having soy sauce, nutty, and umami notes.

Baijiu holds more than 90 percent share of China’s domestic spirits consumption by volume, and Moutai leads the premium end of that market. In global luxury rankings, it has also emerged as one of the most valuable spirits brands worldwide.

In India, Moutai’s presence is currently limited to select duty-free outlets and luxury hospitality settings. However, as Indian consumers become more experimental, especially in metropolitan cities, premium Chinese baijiu brands like Moutai are finding curiosity-driven demand among collectors and high-end diners.

Why it stands out:

- Heritage dating back centuries

- Strong brand equity in global luxury spirits

- Positioned as ultra-premium gifting liquor

Read also Top 10 Best Whisky Brands in Goa That Are Worth Every Sip

Best Low-Calorie Alcohol Brands for Health-Conscious Drinkers

7 Best Japanese Beer Brands in India

2. Wuliangye Yibin Co Ltd – A Refined Baijiu Experience

Another major name among Chinese liquor brands, Wuliangye is known for its “five-grain” baijiu, crafted from sorghum, rice, glutinous rice, wheat, and corn. The result is a layered, aromatic spirit that differs from the bold intensity of Moutai.

Wuliangye has actively expanded into global markets including Europe and Southeast Asia. Its premium positioning makes it suitable for India’s luxury hospitality sector, where chefs and mixologists are exploring Asian pairings and baijiu-based cocktails. As Indian consumers grow more familiar with Japanese sake and Korean soju, the entry of refined Chinese baijiu brands like Wuliangye could represent the next phase of Asian spirits gaining traction.

Why it stands out:

- Unique five-grain production method

- Strong international expansion strategy

- Ideal for curated tasting experiences

3. Tsingtao Brewery – China’s Global Beer Ambassador

Among Chinese beer brands, Tsingtao is arguably the most internationally recognised. Established in 1903, the brewery has a strong export presence in North America, Europe, and Asia. Tsingtao’s crisp lager profile aligns well with Indian food pairings, especially spicy and Indo-Chinese cuisine. In India, the brand is available in select premium retail outlets and high-end restaurants, primarily through imports.

As India’s beer segment evolves and consumers show interest in international lagers beyond European labels, Chinese alcohol brands in india such as Tsingtao, could gradually increase shelf presence.

Why it stands out:

- Over a century of brewing history

- Widely exported Chinese beer

- Balanced flavour suited for the Indian palate

4. Changyu Pioneer Wine Company – China’s Leading Wine Producer

When discussing Chinese wine brands, Changyu Pioneer Wine Company is a key name. Founded in 1892, it is one of China’s oldest and largest wineries. Changyu produces Cabernet Sauvignon, Riesling, ice wines, and brandy, catering to both domestic and export markets.

China has steadily improved wine quality over the past two decades, with regions like Ningxia gaining international attention. Changyu’s premium labels are already present in parts of Southeast Asia and Europe, and exploratory interest in India has emerged through wine importers. With India’s wine consumption still relatively low compared to global standards but growing steadily in urban centres, premium Chinese wine brands could find niche demand among experimental wine enthusiasts.

Why it stands out:

- Established heritage winery

- Diverse portfolio including red, white, and ice wines

- Competitive pricing within the premium category

Know more: Top Craft Gin Brands in India with Unique Botanical Blends

Best American Whisky Brands in India

Top 6 Unfiltered Beer Brands in India That Are Worth a Try

5. Luzhou Laojiao Co Ltd – Tradition with Modern Positioning

Luzhou Laojiao is one of the oldest continuously operating distilleries in China. Known for its “strong aroma” baijiu style, it represents traditional craftsmanship combined with modern branding.

The company has been proactive in expanding global awareness of baijiu through cultural promotions and tasting events. In India, interest in such premium Chinese alcohol is still at an early stage, but may grow through embassy events, cultural festivals, and luxury hospitality tie-ups. For consumers seeking the best Chinese liquor beyond mainstream categories, Luzhou Laojiao offers authenticity and depth.

Why it stands out:

- Centuries-old fermentation cellars

- Strong cultural heritage

- Premium gifting appeal

The Road Ahead for Chinese Alcohol Brands in India

India’s regulatory framework for alcohol imports remains complex, with high customs duties and state-level compliance requirements. However, as Indian consumers continue to premiumise their drinking habits, global diversification is inevitable.

While Scotch whisky, Japanese whisky, and European wines currently dominate the imported segment, top Chinese alcohol brands are gradually entering conversations within luxury circles. The success of Chinese alcohol brands in India will depend on education, tasting-led marketing, and partnerships with fine dining establishments.

Baijiu, in particular, may require significant consumer awareness efforts due to its distinctive flavour profile. However, with India’s openness to global cuisine and cocktail experimentation, the category has long-term potential. As cross-border trade and diplomatic ties evolve, more popular Chinese alcohol brands may test Indian waters in the coming years.

Read More - Top Beauty Brands Seeing a Valentine Week 2026 Sales Surge

Top Newly Launched Beer Brands Gaining Attention in India

6 Whisky Brands You Should Stock Up for This Coming Monsoon

FAQs on Top Chinese Alcohol Brands in India

1. What are the Top Chinese Alcohol Brands available globally?

Some of the leading names include Kweichow Moutai, Wuliangye, Luzhou Laojiao, Tsingtao Brewery, and Changyu Pioneer Wine Company.

2. Are Chinese alcohol brands in India widely available?

Currently, availability is limited to select premium retail stores, duty-free outlets, and luxury hotels. Wider distribution depends on import partnerships and regulatory approvals.

3. What is baijiu, and why is it popular?

Baijiu is a traditional Chinese distilled spirit made primarily from sorghum. It dominates China’s domestic spirits market and is considered one of the world’s most consumed spirits by volume.

4. Are Chinese beer brands popular in India?

Chinese beer brands such as Tsingtao have a niche presence in premium restaurants and imported beer sections, but they are not yet mainstream in India.

5. Is premium Chinese alcohol expensive in India?

Due to high import duties and logistics costs, premium Chinese alcohol typically falls into the luxury price bracket in India.

Lip gloss is no longer an afterthought in makeup bags. Once seen as a shiny add-on, it has become a standalone must-have — a confidence booster, a quick glam fix, and a finish that no lipstick can quite replicate. Across beauty counters and online carts, lip gloss sales are rising fast, especially among Gen Z and young millennials who want radiance without fuss.

While matte lips had their moment, gloss has staged a strong comeback. Think glass-like shine, juicy colour pops, and formulas that feel more like nourishment than makeup. With the shift toward minimal makeup and skin-first beauty, brands that innovate in texture, finish, and feel are seeing standout traction.

What’s interesting is that consumers aren’t just buying any lip gloss — they’re zeroing in on brands that mix performance with comfort and social-ready shine. In India, the surge is visible across categories from affordable everyday drops to premium, Instagram-friendly picks that go viral overnight.

So, which cosmetic brands are leading this lip gloss boom? Here’s a look at five names carving out real momentum.

What’s Fueling the Lip Gloss Comeback

We used to associate lip gloss with the early 2000s — sticky, sparkly, and super sweet. That image is gone. Today’s glosses are lightweight, hydrating, and often infused with skincare benefits like vitamin E, hyaluronic acid, or botanical oils. Glosses blur the line between skincare and makeup — and that versatility is fueling wider adoption.

Whether you’re pairing it with a full glam look or wearing it solo for a fresh, dewy vibe, gloss feels effortless. That’s why brands that nail texture and wearability are the ones driving sales, not just those with pretty packaging.

Why Indian Consumers Are Glossing Up

Beauty habits in India are shifting. With more people watching tutorials, exploring K-beauty and clean beauty trends, and experimenting boldly on social platforms, lip gloss has become a quick way to update a look without heavy makeup. Gloss solves a modern problem: instant polish without commitment.

Brands that balance gloss shine with hydration (no cracking, no dryness) are the ones Indian consumers keep returning to. And as comfort beauty wins over dramatic statement makeup, gloss sells because it feels good — not just because it looks good.

Top 5 Cosmetic Brands Driving Lip Gloss Sales Surge

1. Fenty Beauty

Fenty Beauty shook up the beauty world by being both inclusive and trend-savvy, and its lip gloss line is no exception. Known for its universally flattering shades and high-impact shine, Fenty’s Gloss Bomb became a social media phenomenon almost overnight. The formulas feel cushiony without stickiness and deliver a mirror-like finish that flatters all skin tones. What sets Fenty apart is consistency — shoppers know what to expect: smooth glide, long wear, and true colour payoff. It’s one of the cosmetic brands that didn’t just contribute to the lip gloss trend — it helped define it.

Read more: 8 Best Luxury Lipstick Brands in India That Are Totally Worth the Splurge

Top International Beauty Brands Expanding Aggressively in India

Best Japanese Skincare Brands Indian Consumers Are Rapidly Switching To

2. Glossier

Glossier’s approach to beauty has always been subtle and skin-centric, making its lip gloss a natural hit among minimalists. Its clear and sheer-tint glosses give that just-kissed look rather than full coverage, which fits perfectly into the modern “no-makeup makeup” ethos. Indian gloss lovers appreciate how it layers over natural lip tones without feeling heavy or sticky. Glossier’s popularity isn’t just about aesthetics — it’s about how the product integrates with everyday routines and feels comfortable for all-day wear. That readability makes it one of the most talked-about cosmetic brands in the lip gloss category.

3. NYX Professional Makeup

NYX knows what trend-savvy shoppers want — quality formulas without premium price tags. Its lip gloss range covers everything from clear, glass-shine finishes to rich, bold hues packed with pigment. Because NYX targets young, expressive consumers, its glosses often experiment with texture — high shine, shimmer bursts, even jelly finishes. This excitement translates into high sales, especially among online audiences who love posting lip swatches. NYX combines playfulness with performance, which is why it’s one of the lip gloss brands consumers reach for first when they want vibrant colour and shine without compromise.

4. MAC Cosmetics

MAC has deep roots in professional makeup artistry, and that expertise shows in its lip gloss lineup. Glosses from MAC balance shine with wearability — meaning you get that high-impact finish without a heavy feel. Plus, the colour range is expansive, so you can find everything from soft nude to dramatic berry gloss. What keeps MAC competitive is its ability to satisfy both casual gloss lovers and makeup professionals who need a reliable finish for shoots, events, and editorial work. For many shoppers, MAC isn’t just a brand — it’s a trusted beauty staple, and its glosses are often the go-to choice for skin that needs a polished pop.

5. PAC Cosmetics

PAC Cosmetics brings pro-level formulas into everyday beauty routines, and its lip glosses are no different. Known for rich pigment and smooth texture, PAC glosses offer a hybrid feel: they add shine while enhancing natural lip tone and structure. The brand’s focus on performance — long wear, comfortable feel, and blendability — resonates with consumers who want results without heaviness. PAC’s lip glosses have become conversation starters in beauty communities precisely because they deliver impact without high maintenance, making the brand a key driver in India’s lip gloss surge.

Read also Top Chinese Alcohol Brands Entering India’s Premium Spirits Market

Top American Fashion Brands Expanding Aggressively Across India’s Fashion Retail Market

Top 5 Japanese Electronics Brands with Strong India Presence

Market Insight: Gloss Is More Than a Trend — It’s Becoming a Routine Staple

There’s a subtle shift happening in beauty routines: people are moving away from heavy lip colours toward finishes that look alive and wearable. Gloss has caught that wave. Whether it’s tinted shine over a bare face, layered over lipstick for dimension, or matched with a full makeup look, gloss now has a place in everyday beauty.

Another factor? Social media. Gloss looks bold on camera without effort — it catches light, shows texture, and looks fresh in videos and selfies. That visual advantage has translated directly into stronger online sales, especially among younger buyers.

Finally, consumers are more educated than ever. They’re not just chasing shine—they’re looking for hydrating formulas, smooth glide, and wearability. Brands that deliver on all three are the ones that are seeing repeat purchases, not just first-time buys.

Conclusion

The surge in lip gloss sales shows how beauty has become more experiential and skin-connected. Gloss isn’t a fad. It’s a finish that fits multiple styles — minimal, bold, classic, or experimental. The cosmetic brands driving this surge understand one thing: shine only matters if it feels good. And that’s why gloss is no longer an accessory — it’s a staple.

FAQs

1. Why is lip gloss becoming so popular again?

Gloss gives instant shine and polish with minimal effort, fitting modern beauty preferences for natural yet elevated looks.

2. Are more people choosing glossy finishes over matte lips?

Yes. Many find glossy finishes more comfortable and flattering for everyday wear compared to matte options.

3. Do these brands offer glosses suitable for Indian skin tones?

Absolutely. Brands like Fenty and MAC prioritise inclusive shade ranges that work well across diverse tones.

4. Should I wear gloss alone or over lipstick?

Both work — gloss can stand alone for a soft, natural look or be layered over lipstick to add dimension and shine.

5. What should I look for in a lip gloss?

Look for hydration, smooth texture, lasting shine, and a feel that doesn’t dry out your lips — those are the glosses that get used again and again.

Valentine’s gifting has evolved. It’s no longer just about roses and heart-shaped boxes. People are choosing gifts that reflect personality — something fun, something indulgent, something wellness-led, or something that upgrades everyday rituals.

This year, the most interesting Valentine’s Day gifts aren’t the obvious ones. They’re playful cocktails in a bottle, glow-boosting skincare, pro-grade makeup, and feel-good snacks you can share during a Netflix date. Whether you’re planning a romantic evening or celebrating self-love, brands are stepping up with options that actually feel personal.

Gifting Is Getting More Experiential

Consumers aren’t just buying products — they’re buying moments. A ready-to-drink cocktail becomes a party starter. A luxe face oil becomes a nightly ritual. A wellness snack becomes part of a cozy movie marathon. Valentine’s gifting now revolves around shared experiences and everyday indulgences.

That’s why the best brands offering Valentine’s Day gifts this year span across food, beauty, wellness, and lifestyle. They make celebrating love feel effortless.

Wellness and Indulgence Are Coexisting

There’s also a noticeable shift toward “better-for-you” gifting. Couples want treats — but they don’t necessarily want the sugar crash that follows. Millet-based snacks, antioxidant-rich skincare, and nutrient-focused treats are stepping into the Valentine’s spotlight.

At the same time, indulgence hasn’t disappeared. It’s just been refined — high-performance makeup, artisanal skincare oils, and curated body serums now compete with traditional gift hampers.

Presentation Still Matters

Let’s be honest: how something looks still influences what ends up in the cart. Bright cocktail bottles, sleek beauty packaging, and aesthetically pleasing snack assortments make gifts feel Instagram-ready before they’re even opened.

With that in mind, here are the best brands offering Valentine’s Day gifts that strike the right balance between fun, thoughtful, and practical.

1. BuzzBallz

BuzzBallz are pure festive energy packed into a single, eye-catching bottle. Bright, playful, and impossible to ignore, these ready-to-drink cocktails are made for spontaneous celebrations. Flavours like Chilli Guava Groove and Berry Lemon Squeeze bring a bold twist to classic Valentine’s sipping, making them perfect for house parties or intimate at-home dates. They work beautifully as add-on gifts or quirky surprises when you want something less traditional. Instead of predictable wine bottles, BuzzBallz offer personality — compact, vibrant, and designed to spark conversation before the first sip even happens.

2. Healthy Master

Healthy Master redefines Valentine’s indulgence for couples who prefer mindful choices. Known for millet-based and wholesome snacks, the brand blends nutrition with comfort. From butter-rich millet cookies to gluten-free pasta alternatives and crunchy peri-peri millet balls, every product feels like a smarter swap without losing flavour. Their snacks are perfect for shared movie nights, cozy cooking dates, or curated grazing boards. What makes Healthy Master stand out is its ability to make wellness feel celebratory rather than restrictive. It’s gifting that says “I care about you” — without sacrificing taste or fun.

3. PAC Cosmetics

PAC Cosmetics brings professional-grade beauty into Valentine’s gifting. The Pro Finish Full Coverage Foundation is trusted by makeup artists for a reason — it delivers high pigment payoff with a surprisingly skin-like finish. Lightweight yet impactful, the formula evens out complexion, blurs imperfections, and controls oil without feeling heavy. It’s designed for long wear, meaning it stays put through dinner dates, events, or all-day celebrations. For partners who love beauty or take their glam seriously, PAC Cosmetics offers something far more thoughtful than a random makeup kit — it’s performance, precision, and polish in one bottle.

4. SQIN Botanicals

SQIN Botanicals taps into timeless beauty rituals with its Kumkumadi Oil Anti-Aging Ayurvedic Face Oil. Infused with saffron and traditional herbal blends, this rich botanical formula deeply nourishes while supporting radiant, even-toned skin. It’s not a flashy gift — it’s a meaningful one. Ideal for skincare enthusiasts, the oil enhances luminosity and fits seamlessly into nighttime self-care routines. Gifting SQIN Botanicals feels intimate because it encourages daily moments of care. Instead of a one-day gesture, it becomes part of a lasting ritual — glow that builds quietly over time.

5. Boofootel

Boofootel approaches Valentine’s gifting from a self-love-first perspective. Its SOOPER DUO — a face and body serum set — is designed for head-to-toe glow, making it feel more curated than a single-product gift. The glow-boosting face serum works on brightening and evening skin tone, while the skin-smoothing body serum focuses on firmness and repair. Together, they create a complete routine rather than a quick fix. For partners who enjoy skincare that feels effective yet uncomplicated, Boofootel offers something practical, modern, and genuinely thoughtful — the kind of gift that gets used long after Valentine’s Day is over.

Market Insight: Why Valentine’s Gifting Is Expanding Beyond Chocolates

Valentine’s Day retail has widened beyond florals and confectionery. Beauty, wellness, ready-to-drink beverages, and functional snacks are seeing stronger traction as consumers look for gifts that feel usable rather than symbolic. Brands that combine visual appeal with real value are winning attention. There’s also a clear preference for products that can be experienced immediately — whether that’s sipping, snacking, or starting a skincare routine the same evening. Valentine’s shopping is less about grand gestures now and more about curated, personality-driven picks.

Conclusion

The best brands offering Valentine’s Day gifts this year understand one thing clearly: love isn’t one-size-fits-all. Some couples want playful cocktails. Some want glow-boosting skincare. Some prefer nutritious treats they can share guilt-free. The smartest gifts are the ones that fit into real life — something you’ll actually use, enjoy, or remember beyond February 14. When gifting feels personal, it doesn’t need to be extravagant. It just needs to feel considered.

FAQs

1. What are trending Valentine’s Day gift categories this year?

Beauty, wellness snacks, skincare rituals, and ready-to-drink beverages are trending strongly.

2. Are wellness gifts suitable for Valentine’s Day?

Yes. Many consumers prefer nutritious or skincare-based gifts that feel thoughtful and usable.

3. Is makeup a good Valentine’s gift option?

Professional-grade beauty products make great gifts, especially for partners who enjoy makeup.

4. What makes a Valentine’s gift feel thoughtful?

Practicality, personal relevance, and the ability to create shared experiences make gifts more meaningful.

5. Are experiential gifts becoming more popular than traditional ones?

Yes. Products that create moments — like cocktails, skincare rituals, or shared snacks — are increasingly preferred over traditional items.

Tier II and III cities are fast becoming the engine of India’s next beauty boom. Rising disposable incomes, increased digital exposure, and growing aspiration are driving consumers in these regions to seek premium salon experiences. What was once considered a peripheral market is now a strategic growth frontier, as consumers demand quality services tailored to their lifestyles and local realities.

This shift calls for a new playbook, one that empowers professionals through skill development, builds brand-salon partnerships, and redefines how beauty businesses connect with India’s expanding consumer base.

Understanding the Tier 2 Beauty Consumer

Consumers in smaller cities are value-conscious yet quality-driven. They prioritise services that deliver visible, long-lasting results rather than fleeting indulgence. Trust plays a central role in their decision-making, built through salon recommendations, peer endorsements, and local influencers, not just traditional advertising.

To win their loyalty, brands must align with these pragmatic expectations: focus on product efficacy, transparency, and consistency. The goal is to convert first-time trials into trusted, repeat rituals through performance and partnership.

Role of Salons as Beauty Educators

In Tier 2 India, salons are not just service providers, they are the first point of education for skincare and haircare. Clients often rely on stylists to explain ingredient benefits, recommend regimens, and tailor advice to local needs.

This underscores the need to upskill salon professionals. Training them to understand formulation science, product ingredients, and safe application practices builds both expertise and credibility. Empowered stylists become brand ambassadors who drive informed consumer choices and loyalty.

Product and Service Customisation for Tier 2 Markets

Localisation is the new luxury. Salons must tailor offerings to regional concerns, dryness in arid zones, humidity-related scalp issues, or pigmentation caused by high UV exposure. Professionals who understand these nuances can design context-specific treatments that feel personal and relevant.

Premiumisation also works differently in these markets. Smaller pack sizes, affordable bundles, and multi-use products make aspirational experiences accessible. Consumers appreciate products that simplify life, those that combine treatment and daily care, without compromising on results.

Distribution and Accessibility

For brands to scale sustainably, reliable last-mile delivery is essential. Investing in regional warehouses, local distribution partners, and robust logistics systems ensures that salons never face stockouts, especially during peak demand seasons like wedding or festival periods.

This operational reliability builds trust, allowing salon owners to focus on their craft instead of supply concerns. Over time, supply-chain dependability becomes a competitive advantage.

Regional Marketing That Feels Local

Authenticity wins attention in smaller cities. Effective outreach must reflect local language, festivals, and cultural references. Campaigns that feature micro-influencers, salon owners, and community creators resonate more than generic celebrity endorsements.

Such hyperlocal storytelling drives word-of-mouth, positioning brands as allies that understand and celebrate local beauty traditions, not outsiders selling imported trends.

Digital Discovery Meets Offline Experience

Tier 2 consumers often discover beauty trends online but rely on in-salon validation before making a purchase. The path to conversion, therefore, is hybrid.

Smart strategies blend digital inspiration with offline experience, for instance, using online tutorials to spark curiosity, followed by in-salon demos to reinforce credibility. The goal is to make digital engagement and physical experience complementary, not competitive.

Sustainability That Makes Sense for Tier 2 Salons

For Tier 2 salons, sustainability is less about global statements and more about practical efficiency. Water-saving rinses, refillable packaging, and local sourcing reduce both cost and waste.

Stylists often share simple “green hacks” during consultations, subtly building emotional connection with customers who value responsibility in everyday choices. Distributors can support this by introducing returnable containers or refill programs, turning sustainability into a shared profit and purpose model.

Training & Retention of Salon Talent

Bridging the skill gap between Tier 2 and metro salons is mission-critical. Consistent, certified training not only elevates service quality but also instills professional pride among stylists.

Brands can play a decisive role here, by co-creating training modules, certification programs, and career growth paths. When stylists see tangible progress in skill and income, retention improves, creating a more stable ecosystem for everyone involved.

The Way Forward: Brands × Salons as Growth Partners

The future belongs to brands that evolve from suppliers to strategic partners. By co-funding education, marketing, and local innovation, brands can build trust-based ecosystems that sustain growth across India’s next 500 cities.

The formula is simple but powerful: empowered professionals, local insight, and consistent quality. Together, these elements transform fragmented regional markets into thriving, loyal networks—where beauty is not just consumed but co-created.

As India’s beauty map expands beyond metros, success will depend on how well brands listen, localise, and collaborate. The “Bharat” story isn’t just about scale, it’s about shared growth, skill, and sustainability. For salons and brands ready to adapt, the next wave of beauty is already here, and it speaks every Indian language.

Authored by:

Subham Virmani, Director, Esskay Beauty Resources

Retailers need to develop AI-ready marketing systems in order to be competitive in the market because the nature of the consumers’ market is becoming more dynamic, data-oriented, and discovery-based. Conventional marketing systems can be challenged in dealing with the consumers’ market where the data are fragmented and insights are derived late due to the assumptions made, as opposed to developing AI-enabled marketing systems where data are unified in real-time environments. AI can be integrated into marketing systems in order to provide retailers with clear competitive advantages.

Data Explosion Is Redefining Retail Marketing: Challenges and Opportunities

The modern day retail industry is responsible for the generation of massive data through digital shopping, retail stores, customer loyalty, mobile, social, and support interactions. Research has indicated that the data generated through the retail industry is growing at an annual rate of above 30%, but a large percentage of the data is not fully tapped through the existing systems.

This challenge is resolved by AI-ready marketing platforms through the consolidation of consumer information offered through Customer Data Platforms (CDPs). It has been found that firms that manage the whole of their consumer information experience a 2.5x increase in personalization and a 1.9x increase in surpassing their revenue goals compared to firms operating in silos.

Personalization Is a Revenue Driver Today

Consumer research has repeatedly confirmed that personalization has a direct impact on purchasing behavior. According to surveys, 70-80% of consumers are likely to purchase a brand that does personalized recommendations or communication. Personalization that is irrelevant to customers is a primary reason customers walk away from retail brands.

AI-powered marketing platforms allow a move from traditional segmentation to predictive and real-time personalization. These models involve analyzing customer behavior and data to provide predictive content. Many retail companies that apply AI-driven recommendation platforms reported an improvement in the average order value by 10% to 20%.

Reactive Campaigns to Predictive Marketing

Conventional retail marketing essentially operated on a reactive model, whereby the execution of campaigns took place weeks in advance based on past information. AI retailing breaks the mold as it allows the possibility of predictive decision-making. Studies conducted by leading global consulting houses reveal that the implementation of AI enables retailers to predict customer demand and churn 90% more accurately than rule-based methods.

Predictive analytics enables the marketer to find 'at-risk' customers and provide for timely actions as well as for optimized launch points for promotion, and thereby makes adjustments according to the real-time input received, and this approach enables better ROI for marketing.

Marketing Efficiency and Cost Optimization

The margins in the retailing business are also under pressure because of the increasing cost of acquisitions, discounting, and logistics. The challenge in the retailing business can be met with the help of AI-enabling marketing platforms. Research indicates that the operational cost in marketing operations can be reduced by 20 to 30% with the help of AI.

AI technology is also capable of testing and optimizing various creative assets, audiences, and budgets, a task that manual teams couldn’t execute on a large scale. As a result, retailers can deliver better results without necessarily increasing investments or resources in marketing.

Inventory Alignment and Demand Intelligence

Studies indicate that inaccurate demand forecasting and stock misalignment result in losses of billions of dollars per year for retailers due to lost sales and obsolete inventory. AI-based marketing platforms connected to the supply chain and inventory help retailers synchronize promotional offers and actual stocks.

Predictive models can determine regional demand patterns, seasonal peaks, and item performance, leading to more informed promotion and pricing decisions. Stores utilizing AI demand forecasting reduce inventory shortages by 15% to 25% and boost inventory turnover, thereby influencing bottom-line profitability.

Competitive Advantage Is Becoming Structural

Industry data shows that early leaders in the use of AI for retail marketing are moving ahead at an increasingly rapid rate. The reason for this is that the power of AI multiplies itself as it gets better data, which leads to better models, which then lead to a better customer experience, thus a greater degree of customer loyalty.

Those that fail to transform will commoditize themselves and have to compete solely on price. Experiences, relevance, and responsiveness are differentiators when AI powers the retail experience.

Addressing Adoption Barriers

Despite these advantages, research indicates that adoption is often hindered by challenges such as legacy systems, data-related issues, and skill gaps within organizations. Successful retailers would adopt an AI-ready approach, which could begin with projects such as recommendation, prediction, emails, and churn modeling.

The best practices that are research-supported include investing in cloud martech platforms, developing a strong data governance structure, and leveraging in-house skill development along with external tech collaborations.

AI Readiness: A Strategic Imperative

The reality is that artificial intelligence is no longer a testing environment application; instead, it is a tested means of driving growth in retail marketing. It is now clear that those retailers who are ready to employ artificial intelligence in their marketing activities can expect a refined level of personalization, efficiency, forecasting, and so on.

Authored by:

Priyanka Aeron, Co-Founder, Thrive Global AI

The increased visibility of Ethereum is affecting discussions about digital payments in India's retail economy. For businesspeople and analysts, price awareness has become embroiled in another discussion, ranging from infrastructure to trust and scale.

Retail in India is where rapid digitisation and existing consumer behaviour meet as a challenge and an opportunity. From local convenience shopping to the country's e-commerce platforms, payment behaviour is changing as new technologies redefine how payments are initiated, processed and settled. Digital assets are also included in the debate, not as a tool for speculation, but as a reference resource in the new economy that is programmable finance.

As such, the Ethereum price is now widely referenced in discussions regarding the relevance of blockchain as well as the maturity of blockchain networks, with current market valuations commonly tracked via major exchanges such as Binance. The significance of this cost depends largely on the fact that the innovation associated with digital payment processes is now inextricably linked across this global market.

Reasons why Ethereum Price Awareness is on the Rise in the Indian Retail Sector

Price awareness may well be a result that follows relevance. The growing importance of Ethereum in global technology discourse has led retail industry professionals and research analysts in India to take notice of price-related developments on this network. Such willingness is not based on short-term principles but on indicators of price awareness regarding development participation and resilience.

Trading as of 3rd January 2026 indicates that one Ethereum is equivalent to 3,104.88 US dollars. This is an increase of 0.65 per cent within the last thirty days. This small fluctuation clearly denotes the stable conditions under which the network operates. For the retail onlooker, the information clearly suggests that blockchain technology is moving beyond the experimental stage.

Price awareness, therefore, gets presented in a very context-dependent manner. It can be used to discuss scalability, adoption and long-term sustainability, but it does not necessarily make operational decisions. Retailers are shifting away from seeing this sort of information as a call to action.

The Function of Digital Assets in Establishing Modern Payment Expectations

Digital payments in the Indian economy have seen the light, especially with the penetration of mobile connectivity. In this background, the role of digital assets has been conceptualised in terms of payment systems. Digital assets have provided a conceptual framework for rating payment systems.

In fact, Ethereum, a programmable blockchain platform, is commonly mentioned in contexts related to settlement automation, smart contract execution and transparency. All these factors play a role in shaping expectations, even if existing payment channels are being used. The influence of blockchain in this sector sets a high standard even for system performance and accountability.

A new approach to evaluating payment solutions is to assess their future readiness. The role of digital assets is to provide a clear indication of the possibilities that exist and to influence thoughts and expectations regarding payment solutions.

How Retailers Analyse Ethereum Price Movement Without Speculation

Catalysts in the retail space are approached in an analytical manner. Being reactive is not the focus. Being engaged in the ecosystem is what the price action of Ethereum signifies. A difference here is vital within an environment led by the bottom line and customer satisfaction.

Price trend analysis provides insights into usage patterns on the networks, developer engagement and long-term interest. The data is useful to retailers, providing insights into platform maturity, availability and integration opportunities. This data supports discussions in innovation strategy without adding complexity.

Thus, by viewing price information as information rather than direction, retailers keep their sights on established goals while keeping abreast of technological developments likely to impact future payment structures.

Ethereum Market Visibility and Consumer Trust in Digital Payments

Trust is the key to all transactions in the retail sector. Customers want transactions to be secure, traceable and smooth. Awareness of digital asset markets indirectly affects this by instilling confidence in today’s systems that are driven by technology.

The continued existence of Ethereum throughout various market cycles has led to increased adoption of blockchain-based methodologies. For consumers, knowledge of established blockchains helps solidify their beliefs in digital technology, even when the technology is hidden from view during payment processing.

The retailers find this trust environment helpful for their businesses. As consumers become more familiar with the concept of digital finance, there’s less reluctance to new ways of making transactions.

Speed of Payment, Transparency and Role of Blockchain Systems

The efficiency of payment systems is no longer just about completing the transaction. There is a new dimension of transparency, verification and integrity of data involved. Blockchain technology has impacted this evolution.

The design of Ethereum emphasises the benefit of programmable settlement and transparent flow of transactions. Such aspects are appealing to retail stores that want to understand their supply chain and financial reconciliation processes beyond a simple purchase made through a point-of-sale system.

Even as traditional methods remain the main staple for day-to-day transactions, the influence of blockchain technology is remodelling the notion of visibility and accountability.

What Ethereum Price Charts Indicate Regarding Infrastructure Readiness

Long-term price behaviours can be analysed from the perspective of infrastructure. Having stable performance over long periods of time is indicative of Ethereum being attractive enough for people to contribute their efforts.

Industry analysts also welcome this stability, which helps with deliberations over readiness rather than immediacy. The adoption of infrastructure technology in the retail sector involves gradual acceptance, taking into account compatibility, regulatory standards and staff training.

Price trends are also important in maturity evaluations, because they help determine if technology will be relevant to retailers’ plans and spending over the coming years.

Digital Payment Innovation in the Online and Offline Retail Industry

The retail ecosystem in India is integrated through e-platforms as well as extensive offline networks. Innovation in payments must therefore work effectively across both domains. The impact of Ethereum is often highlighted as being related to interoperability or programmability.

E-commerce retailers examine the role of blockchain concepts in streamlining order automation, reconciliation and settlement. Offline retailers see the impact of evolving digital payment expectations, where the consumer moves effortlessly between channels and devices.

Notably, this convergence calls for the development of flexible, scalable and transparent payment systems. This is where blockchain frameworks come in and offer conceptual models that aid in such development.

Assessment of Payment Innovations by Entrepreneurs in India

Entrepreneurs are essential actors in the process of implementing technology-based solutions. In the retail industry in India, entrepreneurs and operators assess new payment technologies based on feasibility and customer acceptability. Not just on their newness and innovation.

The Ethereum environment is frequently cited as a model of how open systems can facilitate innovation on a large scale. Price awareness drives the assessments discussed in the next sections.

As such, this evaluation process is one of caution and precision. A lot of the entrepreneurs are concerned with stability and user experience while observing retail requirements and developments in digital assets.

Ethereum Price Trends as a Signal of Long-Term Digital Commerce Maturity

The maturity level of digital commerce is shown through consistency rather than innovation. Ethereum's continued presence proves that blockchain technology is evolving from experimental to essential in the digital economy.

For the analyst, the trend in prices is just one piece of information among many that factor into assessing the vitality of the ecosystem.

Within the retail industry, the maturity level reflects an increase in digital payment innovation driven by blockchain concepts, despite the dominance of traditional systems.

Ethereum Network Activity and Retail Scalability Explained

In addition to transparency around pricing, recognition of the need for scalability in the underlying electronic infrastructure is a key concern for those paying attention to Ethereum. Given that modern e-commerce platforms and their supporting technologies are characterised by high transaction volumes and seamless integration across multiple channels, scalability has become critical.

For retail analysts and industry professionals, on-chain behaviour is significant as an indicator of readiness rather than mere potential. The focus on enhancing throughput, efficiency and system synchronisation reflects how the readiness of blockchain infrastructure is being assessed for real-world commercial applications. These include logistics coordination, transaction reconciliation and shared data platforms.

Taken together, these factors make it clear that the maturity of digital commerce depends not only on innovation but also on the strength and resilience of the underlying infrastructure.

The Future of Payment Expectations in India’s Growing Retail Economy